The Role of Heat-Treated Aluminum in Stroke Control Blocks

- Jon Mahurin

- Jul 14, 2025

- 4 min read

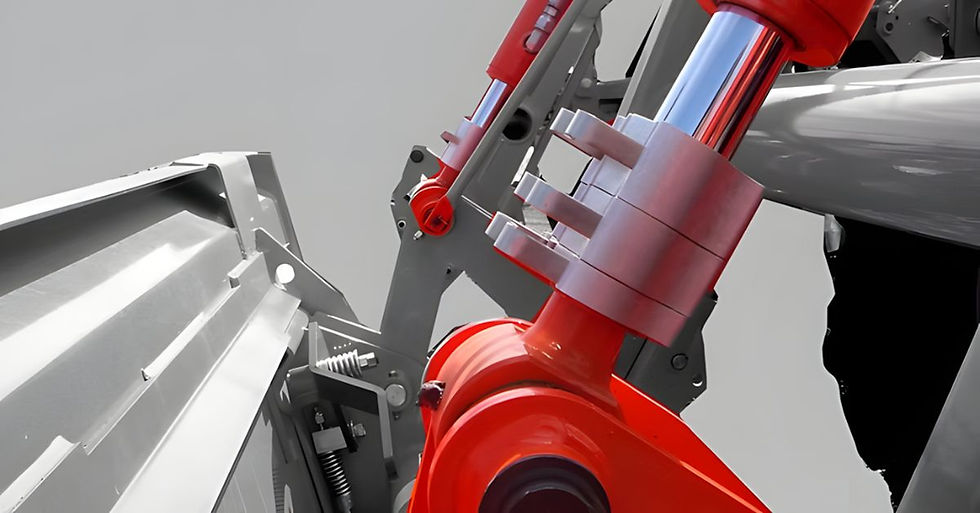

Stroke control blocks play a vital role in countless mechanical systems, often operating under intense pressures and demanding conditions. At the heart of their performance lies a material that enhances their strength and precision like nothing else: heat-treated aluminum.

This remarkable material goes far beyond resisting wear and tear; it actively improves durability, stability, and reliability. The ability of heat-treated aluminum to withstand extreme environments helps ensure that each stroke control block performs seamlessly time and time again. Curious about how it all works? This guide takes a closer look at the unique advantages of heat-treated aluminum and the impact it has on keeping stroke control blocks running at their best.

Strengthening Structural Integrity

When subjected to carefully calibrated heating and cooling cycles, heat-treated aluminum undergoes changes at a molecular level that significantly increase its strength. This allows stroke control blocks to handle immense stress and pressure without cracking or deforming. The enhanced durability offers noticeable advantages, particularly for machinery operating in environments with frequent heavy loads or fast-paced cycles.

Components made with heat-treated aluminum retain their integrity over years of use, which can prevent costly failures. This material both improves the longevity of individual components and contributes to the overall efficiency of mechanical systems. By maintaining its strength in the face of continual demands, heat-treated aluminum allows stroke control blocks to reliably endure conditions that would compromise alternatives made from less robust materials.

Improving Resistance To Wear

Friction remains a constant challenge in mechanical systems, leading to gradual wear on moving parts. Heat-treated aluminum addresses this issue by enhancing the surface hardness of hydraulic stroke control blocks. When properly treated, aluminum develops the ability to resist scratches, dents, and other abrasive damage caused by frequent contact with other components.

This property proves vital in systems exposed to repetitive motions or high-friction environments, as it prevents premature wear that could disrupt operations. The improved wear resistance extends the lifespan of the stroke control block and reduces overall maintenance needs. Operators spend less time replacing worn-out parts, resulting in less downtime for the equipment. Furthermore, by maintaining its original shape and finish, heat-treated aluminum allows stroke control blocks to operate at peak performance throughout their service life.

Enhancing Thermal Stability

Mechanical systems often operate under extreme temperature fluctuations, which can challenge the materials used in their construction. Luckily, heat-treated aluminum offers exceptional thermal stability that allows stroke control blocks to perform reliably in both scorching heat and freezing cold. Unlike untreated aluminum, which risks deformation or loss of strength when exposed to extreme temperatures, the heat-treated version is engineered to resist such changes.

This makes it an ideal choice for industries such as automotive, aerospace, and manufacturing, where temperature control is often beyond the user’s hands. The enhanced stability ensures that the stroke control blocks remain consistent in size and shape, providing predictable, efficient movement no matter the temperature.

Delivering Accurate Precision

Precision is a non-negotiable requirement in many applications, and heat-treated aluminum delivers exactly what you need. Stroke control blocks rely on precise dimensions and consistent structural properties to function correctly. Even tiny deviations in measurements can lead to uneven movement or inefficiency. Heat treatment enhances the uniformity of aluminum, making it a material that manufacturers can count on for producing components with tight tolerances.

This precision proves invaluable in fields such as robotics, medical devices, and industrial automation, where accuracy directly influences results. Heat-treated aluminum allows systems to achieve repeatable motions with minimal variation, ensuring smooth operation time after time.

Reducing Overall Weight

Weight plays a critical role in the performance of many mechanical systems, especially in areas like transportation and aerospace. Aluminum that’s been heat-treated offers a rare combination of lightweight properties and remarkable strength. This makes it an ideal material for stroke control blocks in systems where reducing mass is a priority.

Lighter components place less strain on motors and other driving mechanisms, which improves their efficiency and reduces energy consumption. Heat treatment adds the necessary strength without increasing weight, so the blocks can withstand high loads while keeping the system light. By lightening the load without compromising durability, heat-treated aluminum contributes to more efficient and manageable systems across various industries.

Acting as a Barrier to Corrosion

Corrosion is a natural enemy of metal components, especially in environments exposed to moisture, chemicals, or other corrosive elements. Heat-treated aluminum offers exceptional protection against corrosion, making it an excellent choice for stroke control blocks used in challenging settings.

During the heat-treatment process, the aluminum’s surface becomes more resilient, creating a barrier that resists the effects of rust and chemical reactions. This resistance reduces the risk of damage as well as the need for specialized coatings or treatments to guard against corrosion. Components made with heat-treated aluminum maintain their performance and appearance longer, even in harsh conditions like marine or chemical processing environments.

Saving Costs in the Long Run

Despite an initially higher price point, the benefits of heat-treated aluminum translate to massive cost savings over the lifespan of stroke control blocks. The increased durability, resistance to wear, and reduced maintenance needs all contribute to lowering the total ownership costs. Systems that rely on heat-treated aluminum experience fewer issues, resulting in less downtime and fewer expensive repairs.

Replacement rates for stroke control blocks drop, as the durable material can endure for years without failure. Even day-to-day expenses, like energy consumption, often prove more budget-friendly due to the lightweight nature of aluminum. Viewed as a long-term investment, heat-treated aluminum enables manufacturers and operators to achieve better performance while keeping ongoing costs in check. This economic advantage makes it a go-to choice for applications where efficiency and reliability are vital.

Now What?

The world of manufacturing and mechanical systems revolves around innovation, and materials like heat-treated aluminum are leading the charge. When you think about it, the science behind improving materials is simultaneously about solving today’s challenges and setting the stage for what’s next. Heat-treated aluminum isn’t just a better option for stroke control blocks; it represents how far engineering has come in blending strength, precision, and reliability without compromise.

As design demands continue to evolve, one thing is clear—we’re only scratching the surface of what’s possible with material innovation. Imagine components that are not just durable but adaptable, engineered to advance alongside technological progress. Heat-treated aluminum points toward this exciting future. Whether you’re a designer, an engineer, or just someone intrigued by the mechanics of modern systems, there’s so much more to explore.

Comments